Many people ring and ask "why should I buy a billet sheet metal manifold?" & "what can I gain by buying a manifold?"

Obviously the answer has many variables. So on this page we will give a few examples

Before giving you 2 very good examples there are a number of questions you need to answer before your purchase:

Does your manifold maker have years of experience in the design of manifolds?

Does he have a flow bench and engine dyno for development and testing of ideas and theories?

Does he have years of racing experience?

Does he have an engineering degree?

Does he understand Fluid dynamics?

Does he understand wet flow vs dry flow design differences?

Can he design your manifold to work with other harmonics if runner length is compromised by design requirements?

At BG Engines we are Engine builders. racers and Engineers.

Runner length, taper and plenum size is designed to work with the specific combo in

your engine.

While we do have off the shelf manifolds available for common engine

packages;

we prefer to consult with you and produce a manifold that will meet or

exceed your expectations.

All of our manifold

development starts with basic principles of fluid mechanics and CFD in

conjunction with actual testing via flow bench, the engine dyno, and

track data. . Analyzing all of these variables carefully is

where product refinement, knowledge, and experience increases

with each manifold we produce. We base the foundation of products and

applications around these principles.

Our

small team is made up of someone who has been building race and

street

engines for 30 years, and who has been designing and building manifolds

since 1991. A CNC machinist and programmer with a degree in

Engineering, specialising in Fluid Mechanics and computational fluid

dynamics. Fabricator and welder with many years experience. We have

Flow benches, Fuel flow bench, Superflow 902 dyno and CNC machining

centres. We have years of experience in Drag, circuit and boat racing,

with our own cars and as crew chiefs, mechanics and engine

builders for both factory and private teams.

Back to a few real world examples

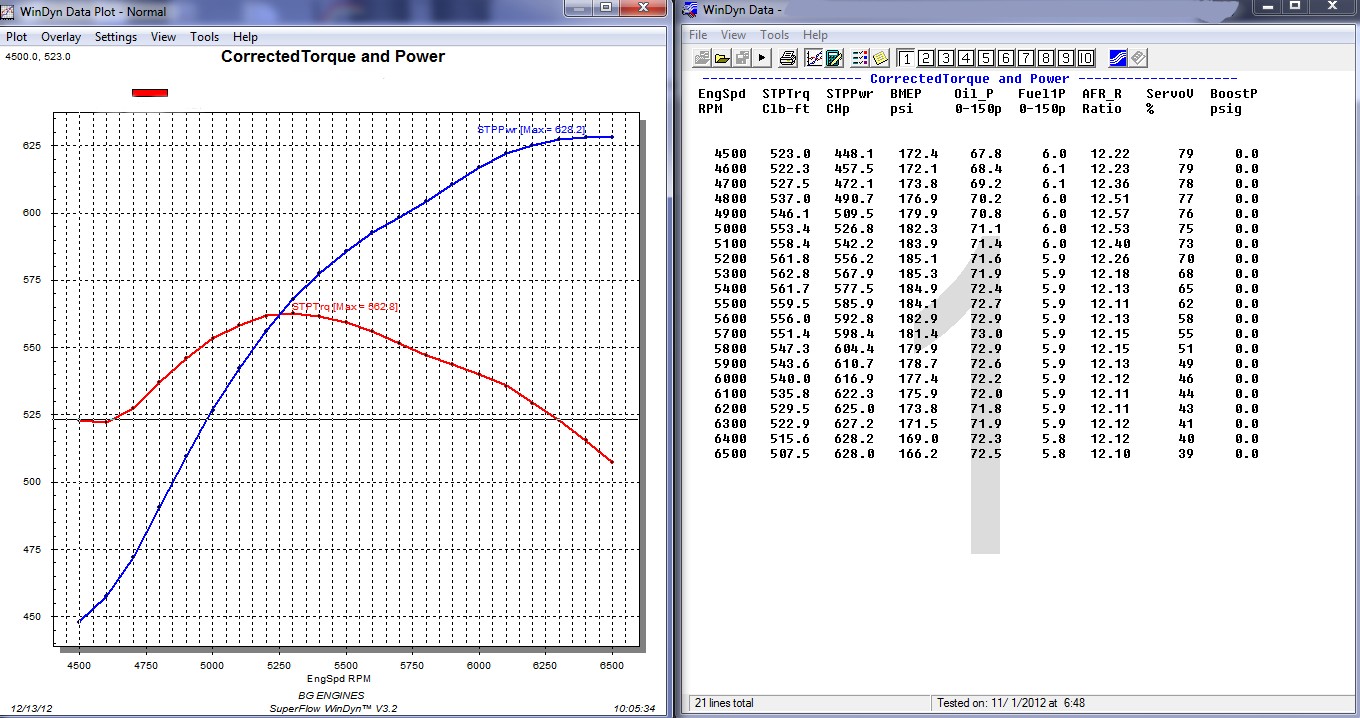

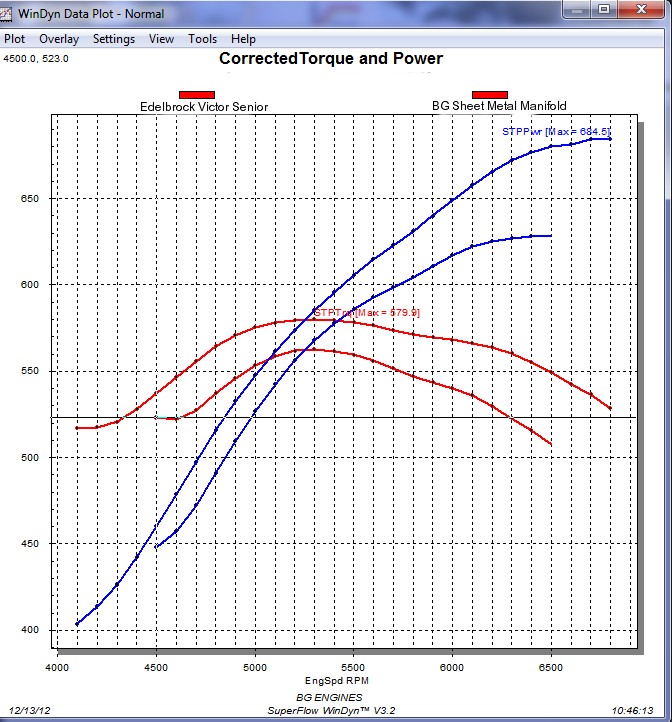

427 Small block Chev with AFR 227 heads.

These heads flow 309cfm which equates to 636 HP

Both engines were the same compression, had the same camshaft and used the same exhaust for dyno purposes

Both Engines used ICE 7 amp ignition systems (ICE Ignitions.com.au)

and ran on BP Ultimate 98 Octane pump fuel

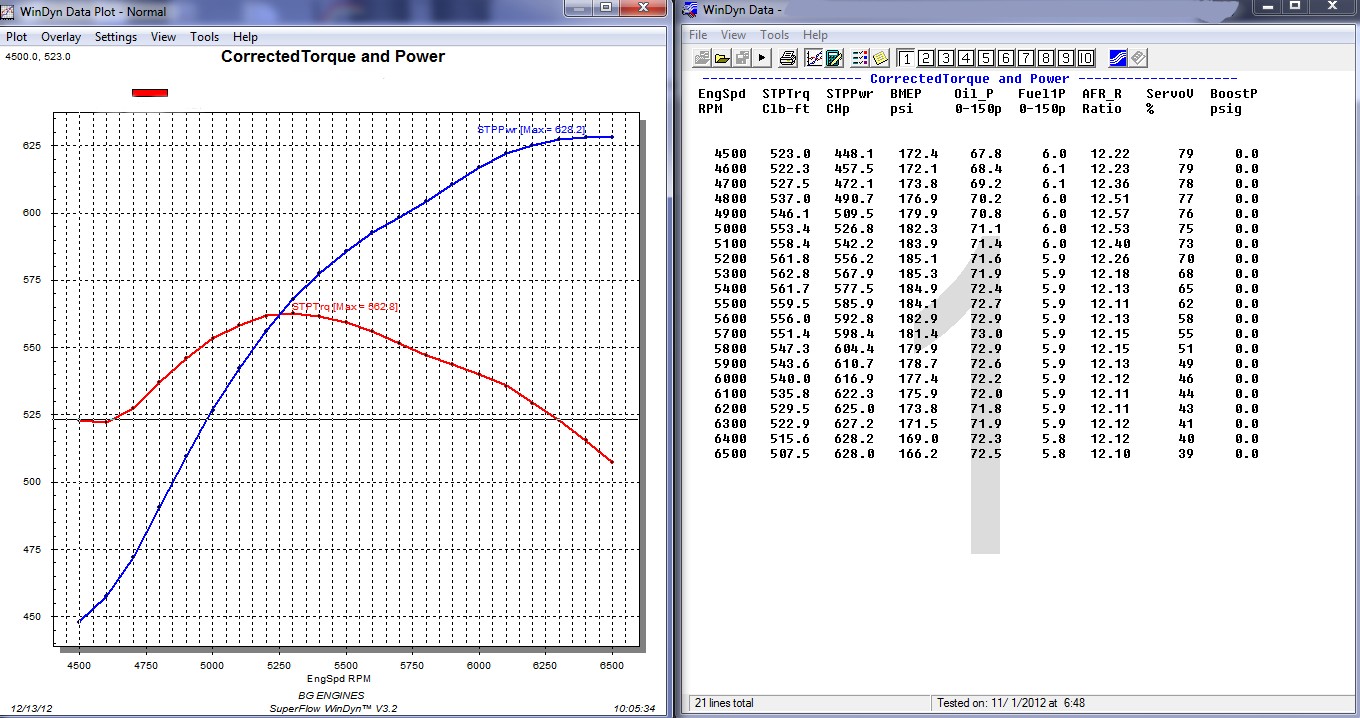

Engine Number one

Edelbrock Victor Senior and Pro Systems dominator carb 628HP

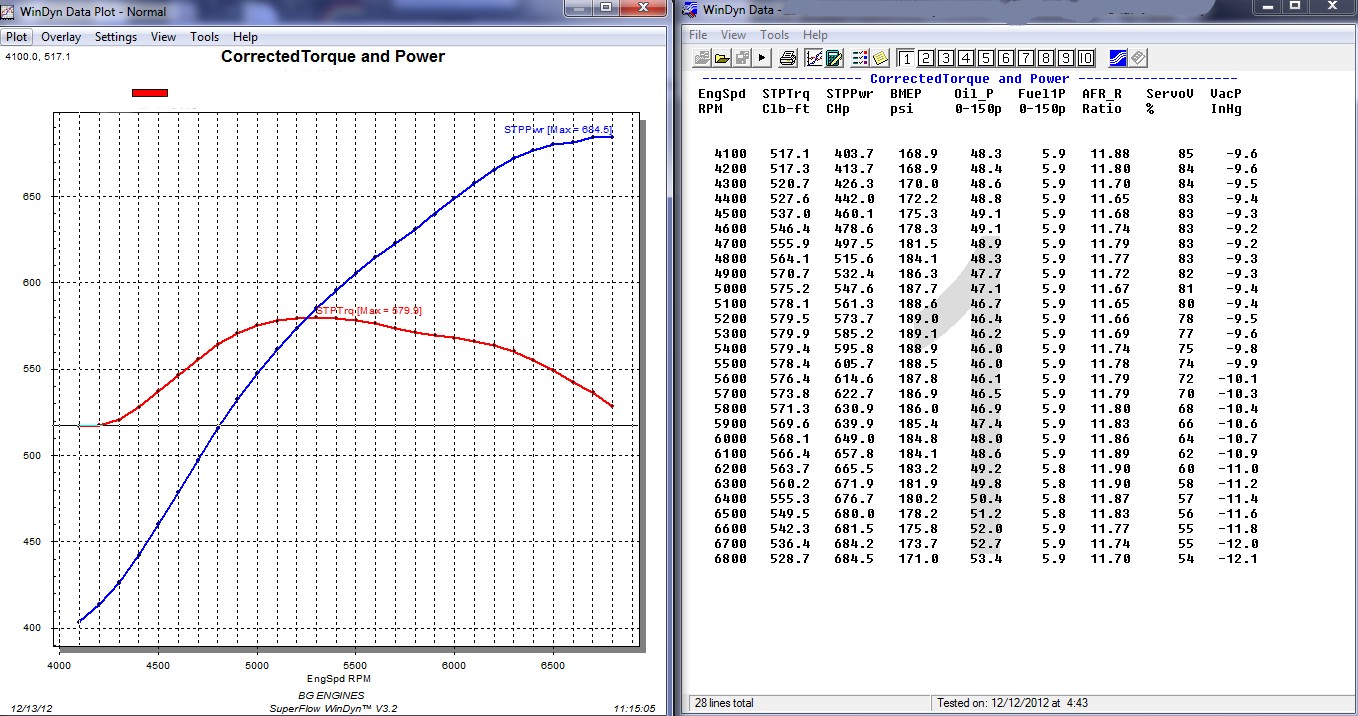

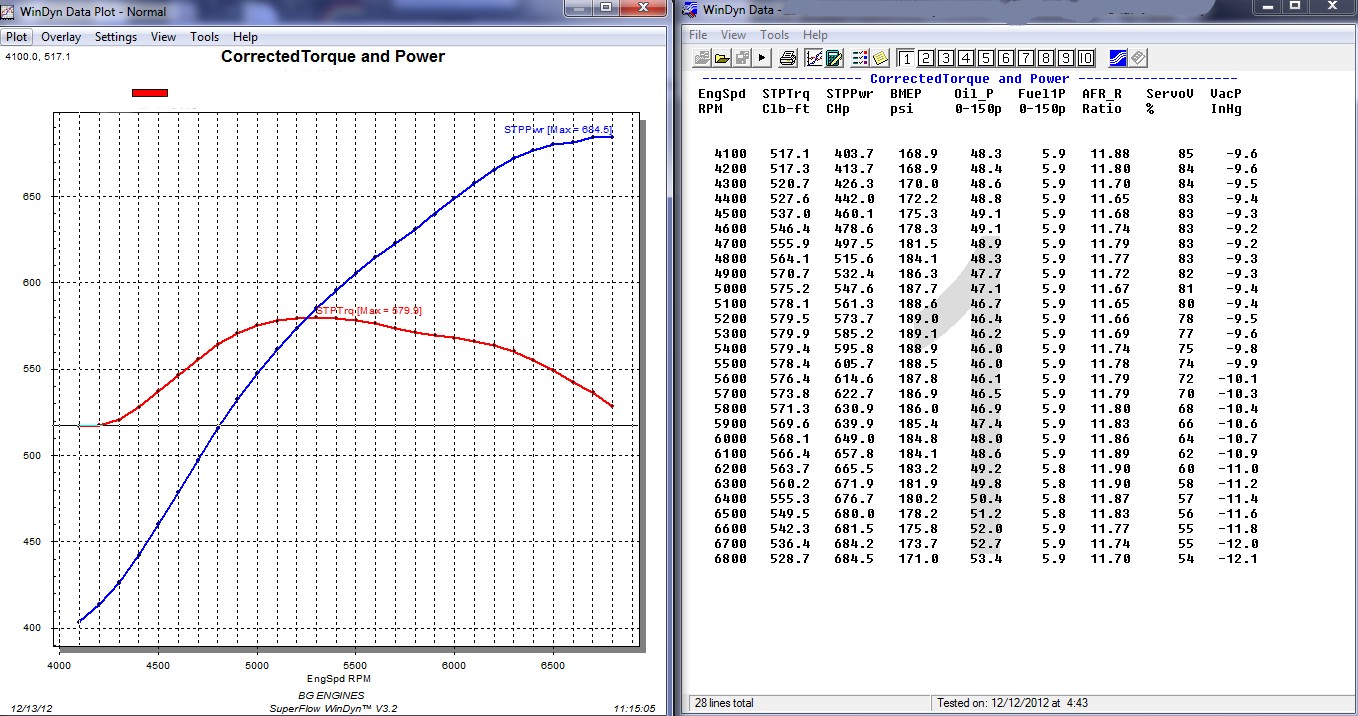

Engine Number 2

BG Custom billet runner sheet metal manifold and 2 holley HP carbs 684 HP

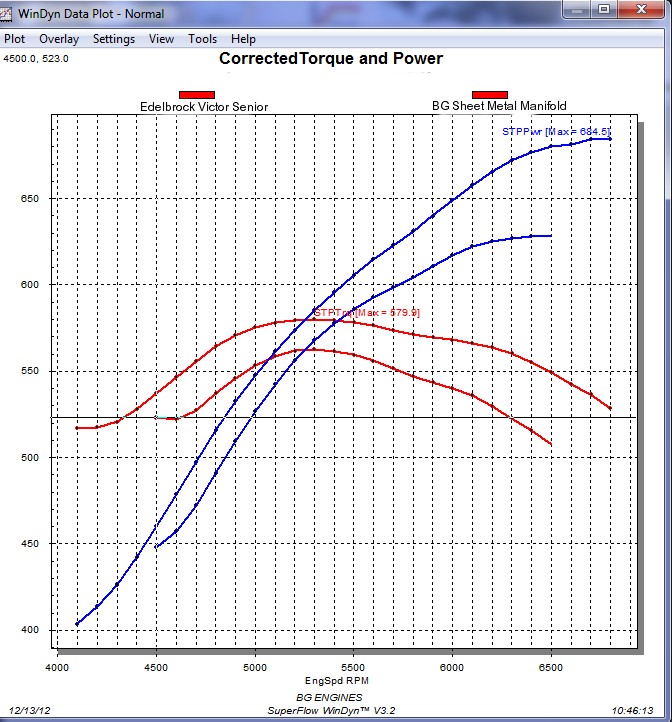

You can see why it is referred to accoustic supercharging, as the

engine makes more HP than the potential of the cylinder heads due to

the ram effect of high pressure waves. A properly designed manifold

can make a huge difference. In this case 56HP, and just as

importantly 15 foot pounds of torque.

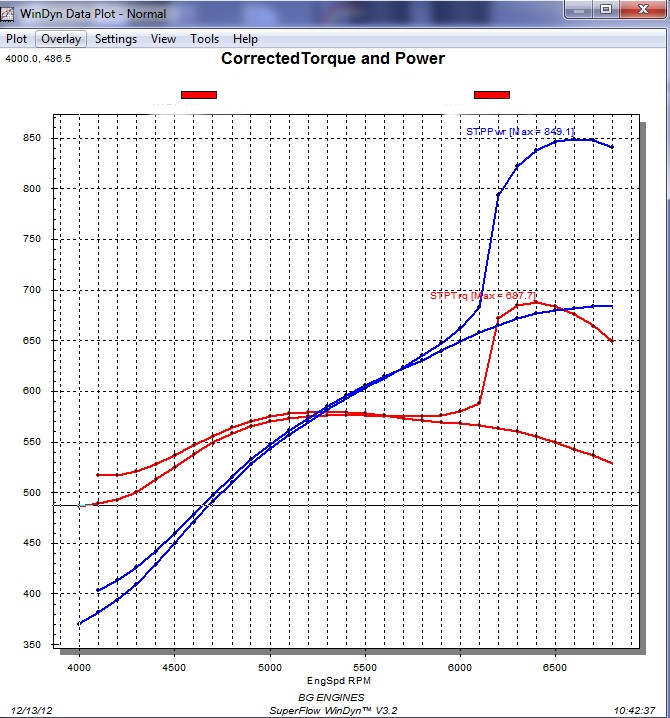

Overlaying The 2 graphs illustrates this difference. Some people are

concerned about losing bottom end power, but as can be seen the BG

manifold NEVER makes less power than the Edelbrock

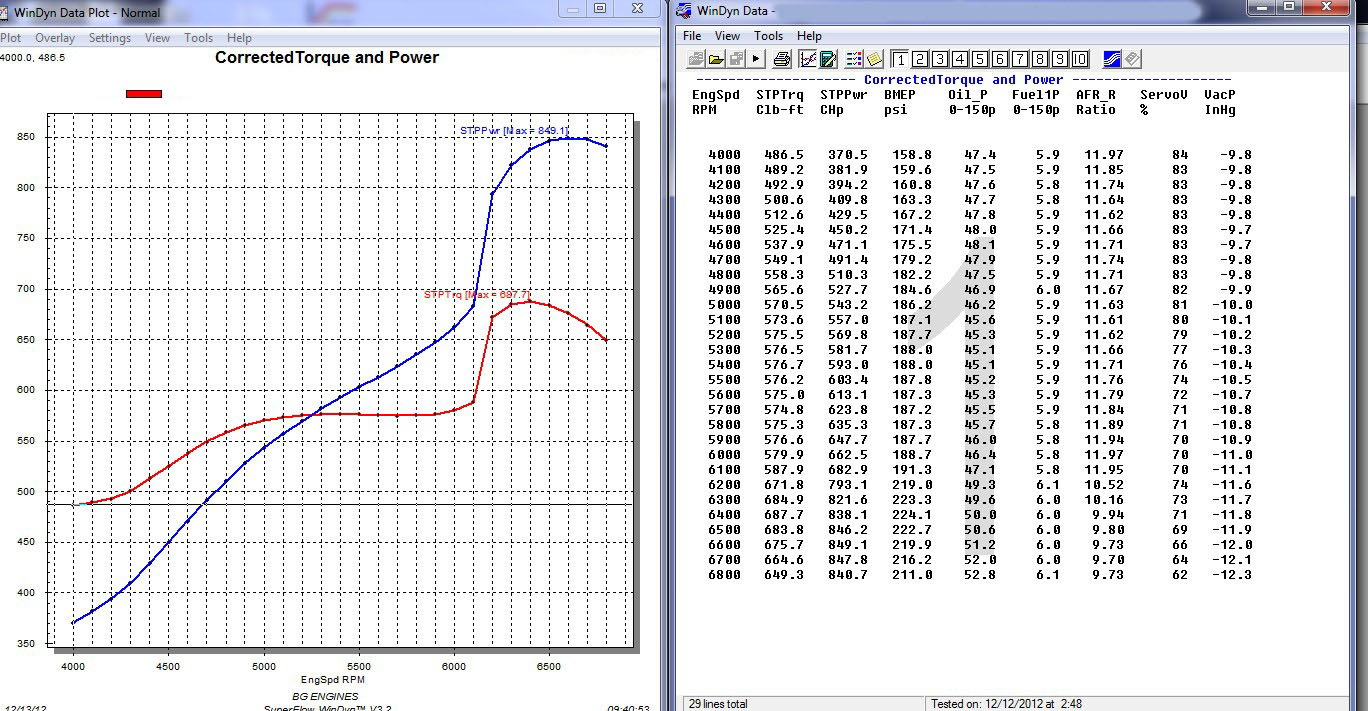

Adding a small shot of nitrous this same engine

Overlaying the 2 graphs

Independent testing confirms and exceeds these figures

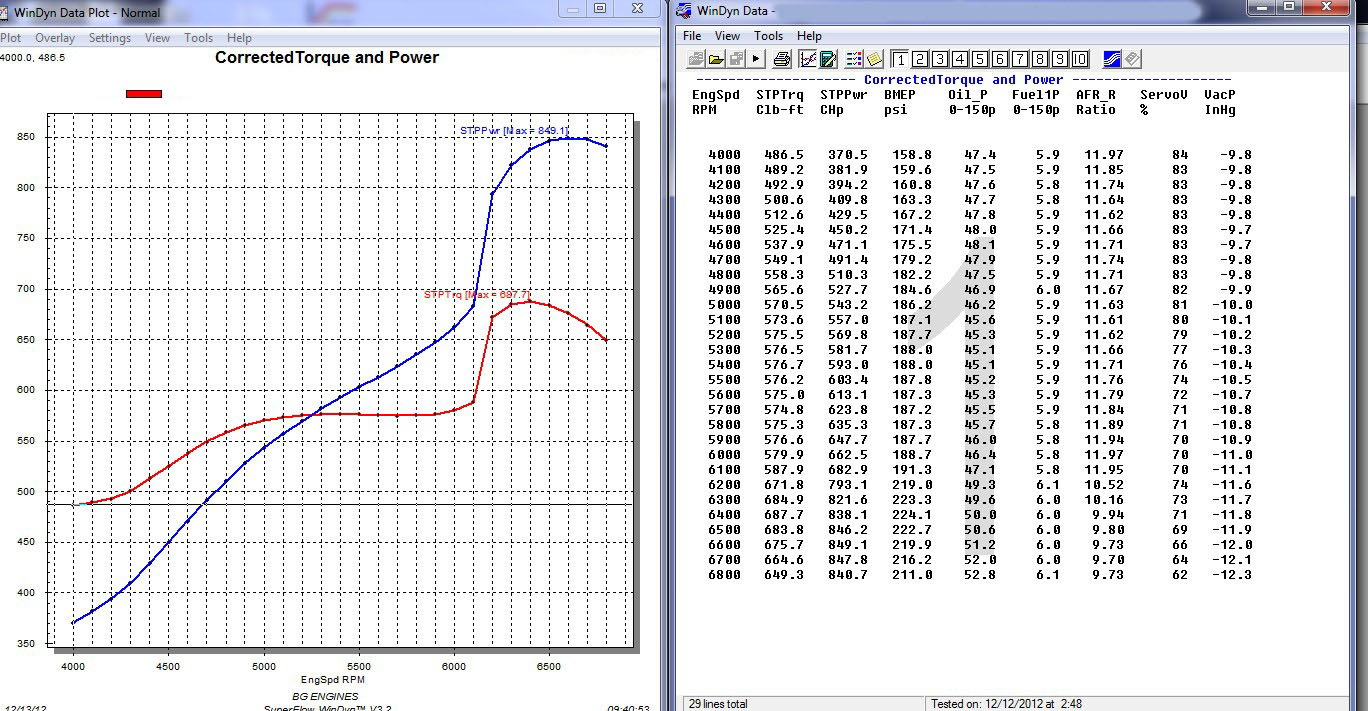

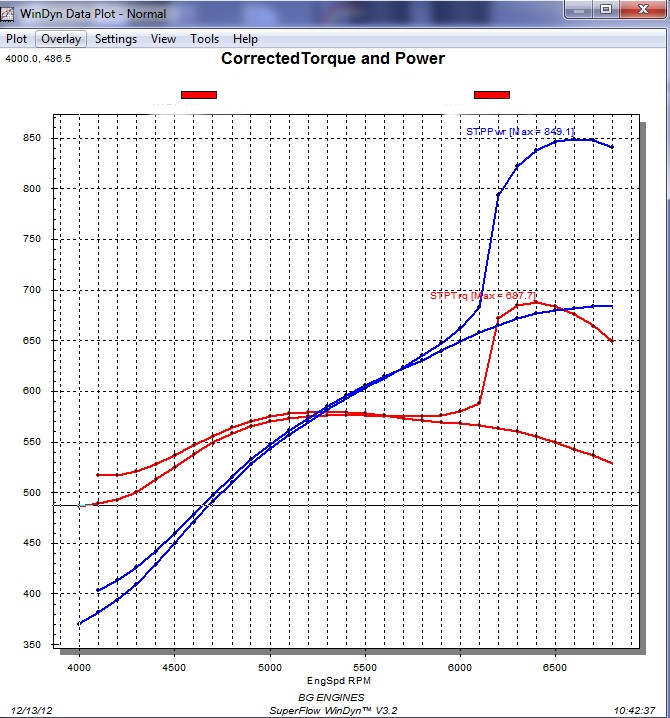

460 cubic Inch Big Paw Holden engine

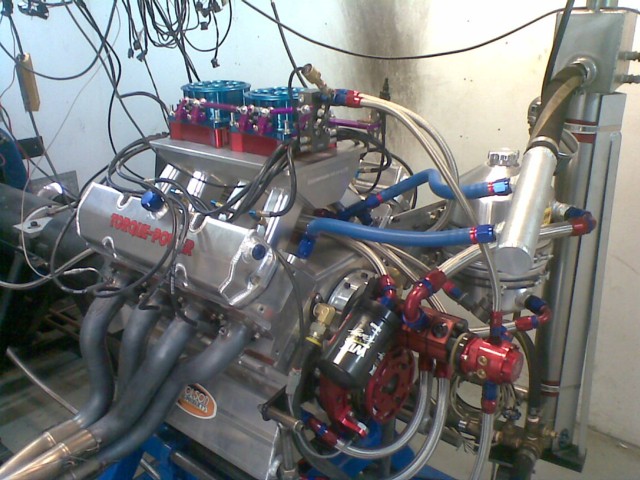

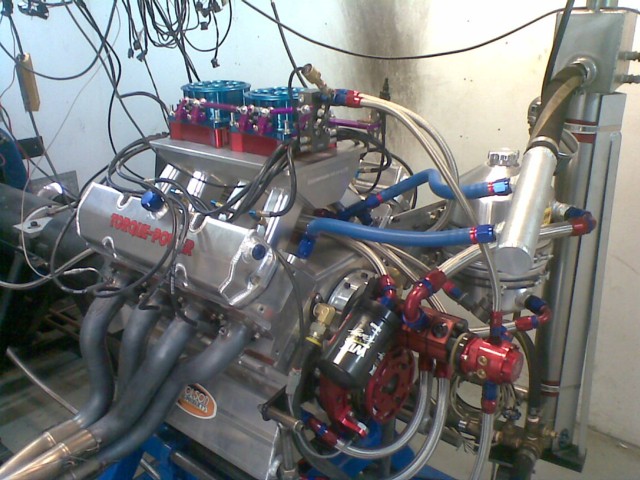

Craig Bennett from Torque-Power

engaged us to build a manifold for twin 1150cfm throttle bodies on a

460 cubic inch Big Paw Engine.

The reults with a cast manifold and a 1450 cfm dominator Dambest carb were:

768HP @ 6300 rpm

665 ft lb

Impressive figures for the big paw dominator single plane manifold

With the BG Billet intake and 2 1150 cfm throttle bodies the same engine made

840HP @ 7200

700 ft lb

Craig's Big Paw Engine, blocks, heads and manifolds combinations are available at

http://www.torque-power.com.au/home.html